1882 when the first version of what we call today ‘The IET Wiring Regulation’ first came to light, (pun) and the “first wiring rules”. At this time, there were scientists were experimenting with electricity, trying to harness its power. This was great voyage of discovery for ways in which electricity can be used.

This led to the emergence of regional electrotechnical societies.

From 1870 to 1890 there was significant growth in these societies and in 1871 the Society of Telegraph Engineers was founded in London. Following several accidents involving industrial and domestic electrical installations, the late 1800s saw the introduction of several wiring standards.

The Wiring Regulations have changed inconceivably since the First Edition was published on 11 May 1882. It’s important to remember, at that time, most houses were illuminated by candle or gaslight and were heated with coal fires electricity was rare in homes and had some issues.

The committee was charged to investigate fires arising from poor electrical lighting installations and to devise some preventative rules to be adopted by the electrical engineering industry at large.

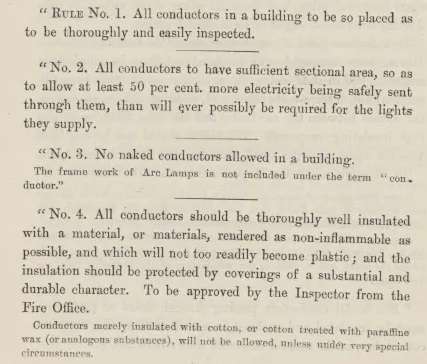

In the first addition of the regulations, there were 19 rules in total.

Five of which were concerned with dynamo machines,

Nine with wiring,

Two with lamps

Three with ‘Danger to Person’.

By 1880 they expanded to become the Society of Telegraph Engineers and Electricians and in 1888 the name had changed to The Institution of Electrical Engineers and in 2006 the IEE merged with the Institute of Incorporated Engineers to become the Institution of Engineering and Technology.

The complications of different standards first came to light at a meeting of the delegates to the International Electrical Congress, in 1904 held in St. Louis, USA.

Documented in the report that “…steps should be taken to secure the co-operation of the technical societies of the world, by the appointment of a representative Commission to consider the question of the standardization of the nomenclature and ratings of electrical apparatus and machinery.”

Consulting engineers preferred their own set of rules. By 1899 there were at least 26 sets of rules in existence for the electrical use and installations.

The International Electrotechnical Commission (IEC) was officially founded at the inaugural meeting at the Hotel Cecil in London in June 1906.

By 1914 there were four technical committees responsible for developing international electrotechnical standards. Despite some interruption to the progress of IEC work due to the First World War, by 1923 there were ten IEC technical committees.

The IEC currently has 207 technical committees developing standards for a wide range of equipment.

TC 64 is responsible for IEC 60364, which is the standard for electrical installations and protection against electric shock. Essentially it is the international version of BS 7671. When developing an international standard, the requirements have to be applied to countries all over the world, it is therefore essential that requirements aren’t too restrictive and that they can be introduced without having a detrimental impact on the electrical industry in a particular country.

Central European Normalization Electrotechnique (CENELEC) is the European Committee for Electrotechnical Standardisation. Designated as a European Standards Organization by the European Commission, CENELEC is an organization set up under Belgian law. It was created in 1973 as a result of the merger of two previous European organizations: CENELCOM and CENEL.

CLC/TC 64 is the technical committee responsible for HD 60364, which is the European standard for Electrical installations and protection against electric shock. This is essentially the European version of BS 7671. The difference between the HD and the IEC publications is that the HD is normative in the UK. This means that electrical installations in the UK are to meet the technical intent of HD 60364.

JPEL/64 is a joint committee managed by BSI and the IET responsible for the development of BS 7671 (The IET Wiring Regulations). Members of JPEL/64 are representatives from a wide range of UK organizations integral to the electrical industry. Many of the requirements that we have in BS 7671 have the same technical intent as the CENELEC HDs.

Standardization is important for several reasons. BS 7671 is first and foremost a safety standard to provide a framework for the electrical industry in the UK and many other countries that have adopted the requirements of BS 7671. Earlier, I mentioned that the first edition of the wiring rules was intended primarily to reduce the risk of fire. However, the focus is now on the whole of product and installation safety and international compatibility.

Over the years the Regulations evolved to incorporate new developments in electrical installations and fittings such as the introduction of the fused 13A plug in the 12th edition (1950).

In October 1992 The British Standards Institution (BSI) and the IEE signed an agreement which made the 16th edition of the IEE Wiring Regulations into British Standard 7671 (BS 7671: 1992 ‘Requirements for electrical installations’).

Since 1992 the IEE (and now the IET) have worked together with the BSI to produce further editions of the Regulations, under the joint technical committee JPEL/64.In 2005 the Government introduced Part P of the Building Regulations entitled ‘Design and installation of electrical installations’.

Part P states that anyone responsible for electrical design or installation work in a home, must make reasonable provisions to protect the persons operating, maintaining or altering the installation from fire or injury.Part P included the following:

In 2015 the 17th edition of BS 7671 saw some major changes from previous editions, which included:

- Maximum earth fault loop impedance values were revised to take account of the introduction of a new correction factor of 0.95 known as Cmin, which is a factor to take account of the minimum supply voltage

- A new Regulation requiring consumer units and similar switchgear within domestic premises to be made from non-combustible material, which saw the deprecation of plastic consumer units

- The reference to ordinary persons was deleted with respect to utilisation classification of external influences

- The introduction of particular requirements for electric vehicle charging installations as a special installation.

The IET Wiring Regulations Eighteenth Edition BS 7671:2018 was published on 1 July 2018. Some of the major changes included:It was specifically stated that ‘metallic pipes entering the building having an insulating section at their point of entry need not be connected to the protective equipotential bonding’. The primary reason for this was to encourage installers/designers to assess installations with respect to extraneous conductive parts as with the use of polyurethane pipes those parts that had previously assumed to be extraneous may no longer be extraneous.

What is rather odd or funny from my perspective is that I learned and qualified in the 90’s and had been working in the industry in the 80’s but had a historical interest in the development of power from a young age. I had access to experiments and reports from the 1800’s and carried out many of them, this was a little before the concept of “risk” had came to my young mind.

The “rules” were always “plain sense” and if you worked in health and safety I also gain my HSE in the early 90’s the common statement about the “rules” is “health and safety gone mad” but with the dumbness of each generation increasing, and the pettiness it seems to have spiraled to detailed “anti idiot with paranoia and such a person to be more than unlucky and prone to near impossible events”..

Slang these days pays a part in the humor as the first editions included “bare conductors”.

Im under the understanding that “bare” means “lots of lots”

It may sound like i was born in the time of dinosaurs but I have seen the first installations of “home electrics” and for the most part these were just light circuits. previously they had gas lights in homes.

The first light switch employing “quick-break technology” was invented by John Henry Holmes in 1884 in the Shieldfield district of Newcastle upon Tyne. The “quick-break” switch overcame the problem of a switch’s contacts developing electric arcing whenever the circuit was opened or closed. Arcing would cause pitting on one contact and the build-up of residue on the other, and the switch’s useful life would be diminished. Holmes’ invention ensured that the contacts would separate or come together very quickly, however much or little pressure was exerted by the user on the switch actuator. The action of this “quick break” mechanism meant that there was insufficient time for an arc to form, and the switch would thus have a long working life. This “quick break” technology is still in use in almost every ordinary light switch in the world today.

Of course we should consider how these were wired firstly.

Bare conductors on the wall, this was then replaced with wrapped cables. this then caused fires. then they made a fireproof cover, this frayed leading to live conductors at the terminals or near to them and then risked shock when thumbing for the switch in the dark.

The switches, arc would be a common thing and having used them, the danger is instilled in my mind from a few light shocks.

Due to how things were wired you could have a live switch and ground surround for the switch, meaning that using it was shocking. as there could be a thin gap between the L1 and N which your hand or finger would complete the circuit.

This image shows a perfect example of fraying and old conductors with “insulation” that cracked with age or fell off. its insulation also included heating, which would lead to fires.

You can learn a bit about wiring here Wires and Cables (edisontechcenter.org)

Fuses or protection was a little protection which spanned from the lightening strikes on telegraphs.

A variety of wire or foil fusible elements were in use to protect telegraph cables and lighting installations as early as 1864. For those who remember the foil wrapped blow wire fuse you can now understand where that came from. but The fuse was patented by Thomas Edison in 1890 as part of his electric distribution system.

You may have seen this type of fuse box growing up and had the cardboard holding fuse wire than you would fit into the fuse when it blew? this “posh box” actually has a surround, where as many did not have any covering let alone a grid “main” fuse. While these are considered as unsafe, people did mess with there power.

The Hansard 06 December 1985 vol 88

(I) draw attention to the fact that, despite the valuable contribution that it makes to modern living, electricity has become an increasingly large factor in household fires. Of all fires reported in 1950, about 7,000 were identified as having an electrical source. By 1970, 17,000 fires were so identified. That represents an increase of 10,000 in 20 years. Only a decade later, in 1980, 35,000 fires were identified as having an electrical source.

A moment’s reflection to consider how rapidly the use of electricity and electrical appliances expanded in households during the 20 years between 1950 and 1970, and the improved safety standards of appliances in the latter part of that period, highlights and puts into perspective an increase in electrical fires of about 17,000 a year by 1980. According to Home Office figures, almost 50 per cent. of domestic fires started by accident are caused by household electrical equipment. In 1983, 173 people died and 2,268 people were injured, sometimes grotesquely, in such household fires—tragedies compounded by our knowledge that almost all those deaths and injuries could have been avoided if the proper measures of care, maintenance and use of electrics in the home had been carried out.”

[ read more ]

the minister goes on to list some of the problems and highlight some of the areas of “power in the home”…

Quite apart from practices such as electric fires and hair dryers being used in bathrooms, there are examples of steam irons and televisions running at the same time from a flex connected to light fittings. Wall sockets hang from the wall because the plaster is so wet from damp that the socket cannot be firmly fixed. Electric heaters are completely covered with dripping wet clothes to dry them faster.

It is surely not beyond the wit of our school system to ensure that, before leaving our institutions of learning, all children know how to change a fuse safely and how to connect a plug and the basic do’s and don’ts of using electricity in the home.

There were 2,350 fires in 1983 that could be attributed directly to the permanent wiring system. This problem is particularly acute in properties that were built and wired more than 30 years ago before the widespread use of plastic-coated wires. Such wiring was sheathed in rubber or it was lead coated. Both materials become brittle with age, which leads to cracking and to the potential uncovering Of wires.

The local consultant for engineering services, fire and accident investigation in Swansea, Mr. Alan Jones, calls the rewirable fuse the damnable, notorious rewirable fuse.

He says that the fuse is like the brakes to a car. It is the fuse that limits energy dissipation, or so it should, but these fuses… are no longer functioning properly. The biggest problem with a rewirable fuse of course is that it can be rewired with anything by anyone.

A 30 amp fuse will take 100 amps for three minutes before it eventually blows.

It means sufficient energy is discharged at the source of the fault to ignite associated combustible materials.

After a fuse has blown a number of times, we have large carbon deposits on the asbestos sleeve together with copper globules which impregnate the lining. So in fact eventually the fuse does not blow at all, and will conduct electricity without any fuse wire in it.

At that point we have lost our electrical breaks, effectively we are driving without breaks, so if you see an article and it says, `The fire was due to a short circuit’, it is wrong, it is not due to a short circuit, the fire was due to the fact that the protective device back at the distribution board did not clear the fault quick enough.

If you see a statement saying ‘the fire was due to cable overheating’, it is singularly and profoundly incorrect. The fire occurred because the rating of the fuse did not tie up with the rating of the cable.

I suppose a useful analogy would be this. If a lorry loses its brakes, careers down a hill and kills 5 people at the bottom it would not be true to say that the accident happened because the lorry was travelling too fast, surely the true cause of the accident was the brakes failing.

No such thing as an electrician

Action is also required to stop the way in which almost anyone can set up as an electrician. There are no nationally recognised formal qualifications for an electrician before he can give himself that title. Perhaps the Manpower 592 Services Commission could organise a formal training course with an approved qualification. Judging by the evidence, many do-it-yourselfers and handymen, on finding themselves unemployed, have set up as electricians. Therefore, such a course would be popular and to the national advantage….It should be mandatory that all electricians who rewire properties should be on the register of electricians

Technical standards for household wiring are laid down in regulations prepared by the Institution of Electrical Engineers and are regularly revised and kept up to date, the most recent edition being produced in 1981. They are concerned with the design, selection, erection, inspection and testing of electrical installations in and about buildings generally. When these regulations are complied with, as is the case with all reputable electricians, the risk to the consumer from the fixed wiring is negligible. The document includes one part devoted to “Protection for Safety”, which is divided into chapters which, among other things, deal specifically with protection against electric shock, thermal effects and overcurrent. However, the regulations are voluntary and not mandatory. Some firms may offer a cheap installation by cutting corners and not complying with the IEE regulations. This raises the question of how the consumer can be protected against bad installation….

The National Inspection Council for Electrical Installation Contracting has been formed specifically to set and maintain the required standard in fixed household wiring. It is a non-profit making organisation, registered as a charity, which was set up in 1956 by concerted action of all sections of the electrical industry. Its aim is to protect the consumer against faulty, unsafe and defective electrical installations. It has a roll of approved contractors containing nearly 10,000 names and addresses of firms which will work to the standards laid down in the IEE regulations.

All contractors who apply for council approval must sign an undertaking that they are prepared to ensure that all their work will conform to the required standard. One of the council’s inspecting engineers then inspects their business premises, staff qualifications, equipment, and a representative selection of their work. Those that pass the examination are accepted as approved contractors on the roll and are then subjected to periodic re-inspection to ensure that standards are maintained. All complaints about the workmanship of approved contractors are investigated.

Summary

As you can see the development of electrical safety has in some ways came from the fact that power in the home is fairly new, it is in my mind, but I’m older and been to homes with no electric or little electric devices at all. I’ve seen the old, the historical and the new and understand the problems and the knee jerk reactions to the problems and the causes. it is fundamental to understand why things are in place as its not maybe for the understanding of the younger generations.

I guess part of this relates to the architect and the builder being slightly different in mindset and skill sets. but some management can be younger and wrong. I often see debates of wright and wrong, where their both right. so there is a wider gap in how things are done.

The “standard” may differ, but often I find myself working towards a higher safety standard and over engineering.

check out the BS7671 post and our IET regulations as they are more up to date and current ( pun).

No responses yet