LFP battery cells, also known as lithium iron phosphate batteries, are a type of lithium-ion battery that utilize lithium iron phosphate (LiFePO₄) as the cathode material and a graphitic carbon electrode with a metallic backing as the anode. Here are some key points about LFP batteries:

- Safety and Durability:

- LFP batteries are highly safe due to their low toxicity and excellent thermal stability.

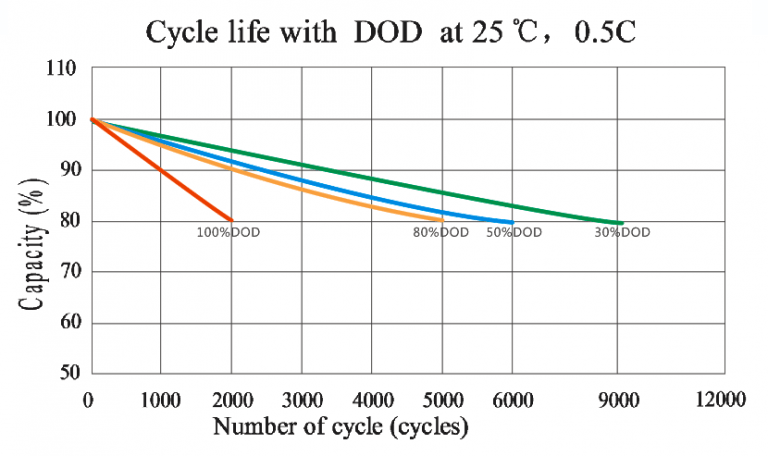

- They have a long cycle life, lasting over 10 years and enduring 2,750 to 12,000 cycles.

- Unlike some other lithium-ion batteries, LFP cells are cobalt-free, which contributes to their safety.

- Energy Density and Voltage:

- The energy density of LFP batteries is lower compared to other common lithium-ion battery types such as nickel manganese cobalt (NMC) and nickel cobalt aluminum (NCA).

- For example, CATL’s LFP battery has an energy density of 125 Wh/kg, while BYD’s LFP battery energy density is 150 Wh/kg.

- In contrast, the best NMC batteries exhibit energy densities of over 300 Wh/kg.

- LFP batteries also operate at a lower voltage than other lithium-ion battery types.

- Market Trends:

- LFP batteries are gaining popularity in vehicle use, utility-scale stationary applications, and backup power due to their low cost and safety features.

- As of September 2022, LFP batteries accounted for 31% of the electric vehicle (EV) market share, with Tesla and Chinese EV maker BYD being major players.

- Chinese manufacturers dominate LFP battery production, and with patents expiring and demand for cheaper EV batteries, LFP production is expected to surpass NMC type batteries by 2028.

- History:

- LiFePO₄ was identified as a cathode material for batteries in 1996.

- Its advantages include low cost, non-toxicity, abundance of iron, and good electrochemical performance.

- The main challenge was its low electrical conductivity, which was addressed by reducing particle size and using conductive coatings.

The shortcomings of LFP batteries

LFP (lithium iron phosphate) batteries, while having several advantages, also come with a few limitations. Let’s explore them:

- Lower Voltage:

- LFP batteries operate at a lower nominal voltage compared to other lithium-ion battery chemistries. Typically, they have a voltage of 3.2 volts per cell, whereas some other lithium-ion batteries operate at 3.7 volts.

- This lower voltage affects the overall power output and compatibility with certain applications.

- Lower Energy Density:

- LFP batteries exhibit lower energy density compared to other lithium-ion types like nickel manganese cobalt (NMC) or nickel cobalt aluminum (NCA).

- Energy density refers to the amount of energy stored per unit mass or volume.

- While LFP batteries may not provide as much energy storage capacity, their long cycle life compensates for this limitation.

- Slower Recharge Rate:

- LFP batteries generally recharge more slowly than some other lithium-ion batteries.

- However, recent advancements have led to LFP batteries achieving charging speeds comparable to standard lithium-ion batteries.

- Heavier Weight:

- LFP batteries tend to be heavier than other lithium-ion batteries due to their specific chemistry and construction.

- This weight can be a concern in applications where minimising weight is essential.

- Limited High-Performance Applications:

- While LFP batteries excel in safety, longevity, and cost-effectiveness, they may not be the best choice for high-performance luxury vehicles.

- Their lower energy density and voltage make them less suitable for applications demanding extreme power output.

In summary, LFP batteries offer a trade-off between safety, durability, and energy density. They are well-suited for many applications, especially when long life cycles and safety are critical, but may not be ideal for high-performance scenarios. However for storage solution’s LFP is very popular.

one of the lesser known and discussed short comings is the charging and low temperature performance of LFP.

Let’s delve into the performance of LFP (lithium iron phosphate) battery cells in temperatures below 10°C. I’ll provide information based on scientific data sources:

- Temperature Impact on LFP Battery Performance:

- The optimal operating temperature range for lithium batteries, including LFP, is typically 0°C to 35°C1.

- When temperatures drop below this range, LFP batteries experience several effects:

- Reduced Activity of Lithium Ions: Cold temperatures hinder the movement of lithium ions within the battery, leading to decreased performance.

- Weaker Discharge Capacity: The discharge capacity of LFP batteries becomes weaker in low-temperature environments.

- Shortened Use Time: Cold weather affects the overall use time of LFP batteries (lower capacity).

- Capacity Drop and Stages Near 0°C:

- At temperatures near 0°C, LFP batteries exhibit specific behavior:

- Temporary Capacity Reduction: If an LFP battery is used in a low-temperature environment for a short period, the damage is only temporary and does not permanently affect battery capacity. The performance typically recovers when the temperature increases.

- Irreversible Damage: However, if the battery is charged and discharged in a low-temperature environment for an extended period, metal lithium can separate out on the surface of the battery anode. This process is irreversible and permanently damages the battery capacity.

- Smartphone Shutdown: Similar to how smartphones may automatically shut down in cold weather to protect their batteries, LFP batteries also exhibit protective behavior provided the BMS is capable of offering protection.

- At temperatures near 0°C, LFP batteries exhibit specific behavior:

- Charge and Discharge Information:

- Discharge Capacity at 0°F (−18°C):

- LFP batteries perform better than SLA (sealed lead-acid) batteries in the cold. At 0°F, lithium discharges at approximately 70% of its normal rated capacity, while an SLA battery discharges at only 45% capacity under the same conditions2.

This is fairly typical use of both types of battery, there being around 5% difference which is almost equal in our opinion.

- LFP batteries perform better than SLA (sealed lead-acid) batteries in the cold. At 0°F, lithium discharges at approximately 70% of its normal rated capacity, while an SLA battery discharges at only 45% capacity under the same conditions2.

- Charge and Discharge Strategies:

- To maximize LFP battery life and efficiency in cold climates:

- Avoid Long-Term Operation: Prolonged charging and discharging in low temperatures can lead to irreversible damage.

- Reinforce Temperature: If an LFP battery experiences temporary capacity reduction due to cold, allow it to recover by reinforcing the temperature.

- Consider Installation Location: For residential installations, consider basements (if dry and code-compliant) due to their temperature stability. Basements often have less extreme temperature swings than garages or carports

- To maximize LFP battery life and efficiency in cold climates:

- Discharge Capacity at 0°F (−18°C):

This above chart shows the effects Higher temperature on the battery capacity. it is important that the environmental factors are taken into consideration when buying ( sizing) you LFP battery.

Abstract: LINK

Derating is widely applied to electronic components and products to ensure or extend their

operational life for the targeted application. However, there are currently no derating guidelines

for Li-ion batteries. This paper presents derating methodology and guidelines for Li-ion batteries

using temperature, discharge C-rate, charge C-rate, charge cut-off current, charge cut-off voltage, and

state of charge (SOC) stress factors to reduce the rate of capacity loss and extend battery calendar life

and cycle life. Experimental battery degradation data from our testing and the literature have been

reviewed to demonstrate the role of stress factors in battery degradation and derating for two widely

used Li-ion batteries: graphite/LiCoO2 (LCO) and graphite/LiFePO4 (LFP). Derating factors have

been computed based on the battery capacity loss to quantitatively evaluate the derating effects of

the stress factors and identify the significant factors for battery derating.

Myths

There are a lot of myths when if comes to batteries, and there are variations to testing, and ratings as well as the chemistry within the battery. LFP used to have a rating of 2000 cycles, now we have 10,000 and a few in between, which is around 4 or 6 thousand.

Off Grid Garage, ran capacity tests on 280ah Eve cells, and the average loss was around 4% over 4 years in normal conditions. However many people think they have “normal” use conditions but are not.

We did some math…..

We worked out that if you bought LA batteries and they lasted X years, that in that time they would have paid for themselves and their replacements, with a profit/saving. While LFP would last longer the timeframe would be longer, and they may meet the replacement costs.

This means that costs wise, life cycles, there is not much difference between the two, other than the price and current delivery and voltage stability.

We hammer down the prices of Batteries while keeping the quality up. it is a hard task, but here are some of our offers in the shop:

5.1kWh Battery Little rack batteries.

15kWh Battery – Ground case – Seplos type.

20 kWh Batteries – 2 x 10kwh wall mounted.

40kWh Battery – Big cabinet battery.

24V 100Ah LFP Battery — RV 301 type.

One response

[…] use with solar, lead acid, LFP and Li-ion.Lead batteries are fairly common as they are in cars, LFP is fairly new and highly popular, and Li-ion have been around a good while now in laptops, phones […]