Going off grid or AC coupled people are looking at “good value” batteries for there homes and projects, and the Nisan leaf price drop means that there is a battery that can be had for a low price. The same goes from most batteries from EVs, but there is a lot more to just unplugging the battery and sticking it on an inverter.

You are more likely to have a Solax inverter as they are the one inverter I know that will take a EV battery voltage. But there is nothing really stopping you breaking the battery packs down to match common inverters power requirements. The leaf due to its easy construction has been popular, But This is NOT the same on all EVs

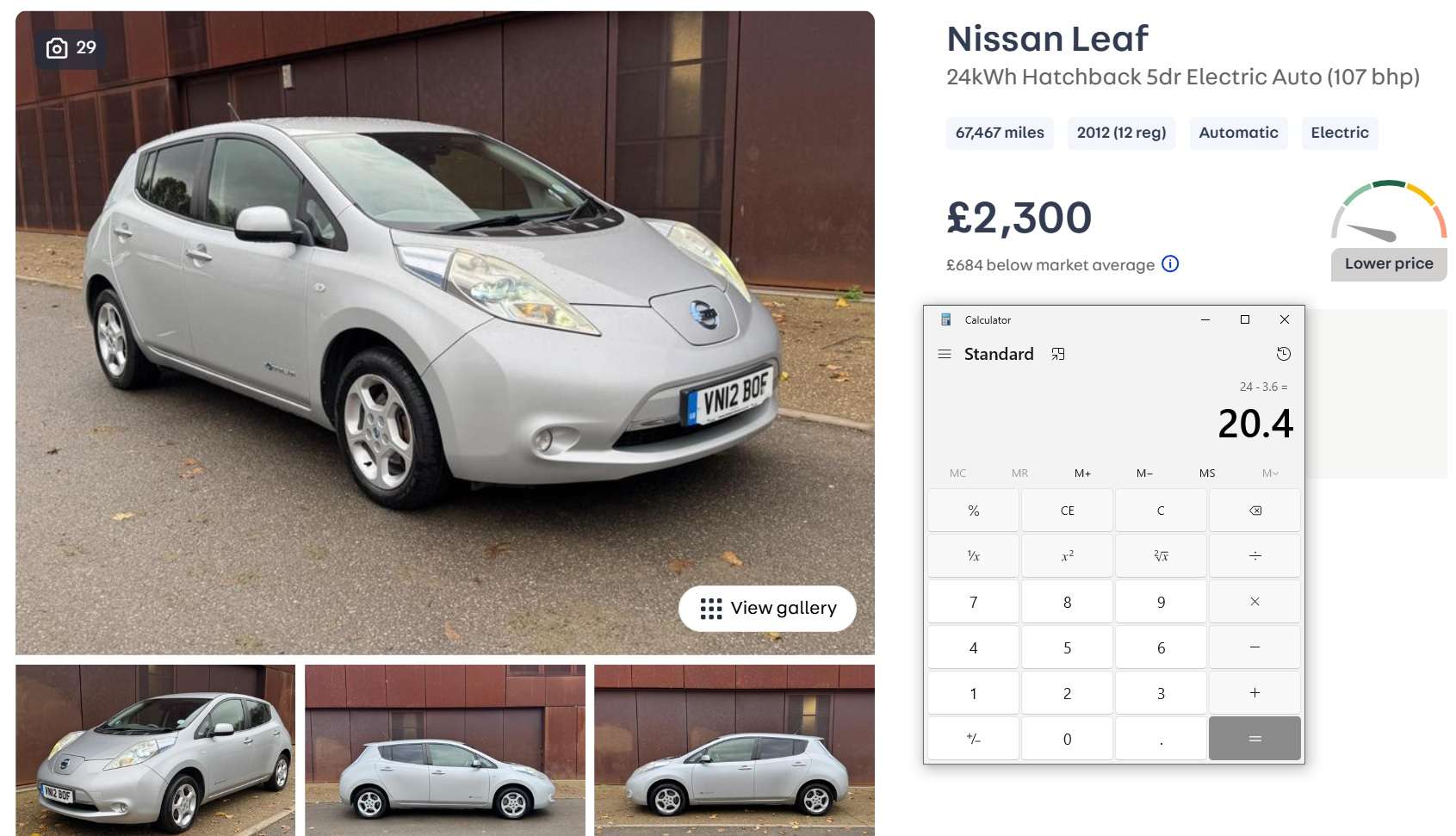

Lets look at the Ad.

£2,300 for a leaf with 85% capacity. So that makes the battery 20.4kWh. or £115 per kWh

Just to give you perspective here; That’s £700 less than our batteries, that are cased, work as a “out of the box” solution which is £147.05 kwh.

Now this used battery is the older pack of battery cells, as the car is a 2012, ideally you want ones which are newer than March 2013.

Currently on Ebay there is a leaf battery only, that had no bids but has only a 42% SOH making this around 10 kWh, However the price of £200 may peak someone’s interest for a DIY build.

There is also a BMW 77KWH battery for £2000 and there are BMW 60V Modules for £179 (pic below)

As you can see in many EV packs the configuration is wrong for many inverters, as you would need a certain cell series based on the battery voltage range. The leaf on the other hand is not cutting laser welds when remaking a battery pack for your inverter.

This pack is listed for £1,150 (11.6kWh) which is £99.13kwh

Battery Configuration.

14 in series for 48V system.

You would parallel the battery packs to increase the current rating which should be greater than the current requirement of the inverter, each module capacity being 50Amps of current. With the above listing giving you effectively 450Amps of current.

(Read about “battery cycle life” ) thus a 8 Kw inverter would run the pack cells at just 18 amps, so that you can have more life from the battery.

This has been the main selling point of using EV batteries which are technically EOL for car use.

Battery Management.

Buying an off the shelf BMS is fairly straight forward and there are a lot to choice from. A 200Amp BMS will cost £120.00

If you have an inverter with communications, you may want a PACE BMS which is also around £120. This way your inverter should support CAN or RS485 and better battery management.

As part of the management you will want a breaker /Fuse as well as bus bars and other hardware to complete the battery pack.

Safety.

With Lithium battery and fires, I would consider making smaller packs with low current BMS protection and running the seperate batteries in parallel. With the BMS costs of around £30, it works out more cost effective to make smaller packs while adding that extra level of protection should anything go wrong.

Is it worth it?

Not really, with £1150 for the 35 modules, making them £32 per module, the total spend would be the same as two of our ready made rack batteries. You will have to make the bus bars and cables, as well as find some container for the used battery and that total would be more than our battery packs.

The risk isn’t that great with the leaf cells, but LFP is a little better. But there are use cases where cold charge temps may come into play?

5.12kWh LFP battery Module £750

Sometimes what seems like a good Idea takes hours of time and adds more cost when new prices are not too far different from used prices.

We did a 18650 battery build, with a cost of £26.36 kWh however this “project” took many hours to complete and of course there are risks when using mixed cells.

But at the end of the day it just was not worth doing. While the leaf modules are certainly easier to work with as would have been new cells.

Perhaps collecting trash vape batteries and making a battery pack would be more of a challenge and bragging rights adding a value of fun.

But with the cost of new cells and the available kits, the costs and value make most used battery options poor value for money.

Different new cell battery build

Remember you can buy LFP cells and build a battery from these new cells.

At £1,208 including a BMS which will give you 15.5kWh Battery, has a costs of just £77.93 kWh

As you can see, value is certainly different when you look at the price per kilowatt hour.

Used 18650 £26.36 kWh (2.4 kwh)

New LFP cells £77.93/£109 kWh (15.5 kwh)

Used leaf cells £99.13 kWh (11.6 kwh)

New battery £147.00 kWh (10.2 kwh)

A battery builder said : If its more than £50 Kwh then its not worth buying used

One response

How to build a battery with a Nissan leaf cells.

Remove the battery cells and use “all thread” or “threaded rod” and the original battery cages to fix the batteries to the desired voltage. 7s for 24v and 13s for 48V.

While you can use the loom from the car, we would recommend using bus bars from copper bar. rated for the current you are drawing from the system, ( inverter kw / battery voltage).

Contact us for custom BMS of 150,200 or 250 amps with Bluetooth and app.

Wire the BMS balance leads as set out in the instruction manual.

And your done!

It really is a simple process the most difficult part is aligning the holes in the bus bars with the battery terminals.

You will need to have ring terminals and a wire crimp tool, so that you can attach the bms balance cables to each of the battery terminals.